The UK’s wind energy sector is growing at an incredible pace, with turbines becoming taller, more complex, and located in increasingly challenging environments. As this industry scales up, so too does the need for safe, efficient, and cost-effective inspection methods.

That’s where drone technology comes in.

At PB Aerial Imaging, we specialise in wind turbine inspections using UAVs, delivering accurate, detailed data that helps operators keep their assets running at peak efficiency — without costly downtime or dangerous manual work.

The Challenge with Traditional Inspections

Traditionally, turbine inspections relied on rope access technicians or scaffolding, which can be:

- High-risk – working at height in exposed conditions is inherently dangerous.

- Expensive – scaffolding, rope crews, and extended turbine downtime all add cost.

- Slow – inspections can take days, delaying maintenance or repair work.

These methods are effective but no longer practical when operators need to inspect dozens or even hundreds of turbines across large wind farms.

The Drone Advantage in Wind Turbine Asset Inspections

By switching to drone inspections, operators gain:

✅ Unmatched Safety – No need for technicians to climb or work at height.

✅ Speed and Efficiency – A full turbine inspection can be completed in under an hour.

✅ High-Resolution Data – Drones capture close-up stills and video of blades, hubs, and towers.

✅ Thermal Imaging – Detect hotspots, cracks, or delamination invisible to the human eye.

✅ Reduced Downtime – Turbines can be back online faster, maximising energy output.

What We Look For

Our wind turbine drone inspections cover:

- Blade Condition – checking for cracks, erosion, lightning strikes, or delamination.

- Tower Integrity – assessing welds, joints, and paint degradation.

- Nacelle & Hub – identifying wear and tear or structural issues.

- Thermal Defects – pinpointing internal faults before they become critical failures.

This comprehensive approach gives operators the evidence needed to make proactive maintenance decisions.

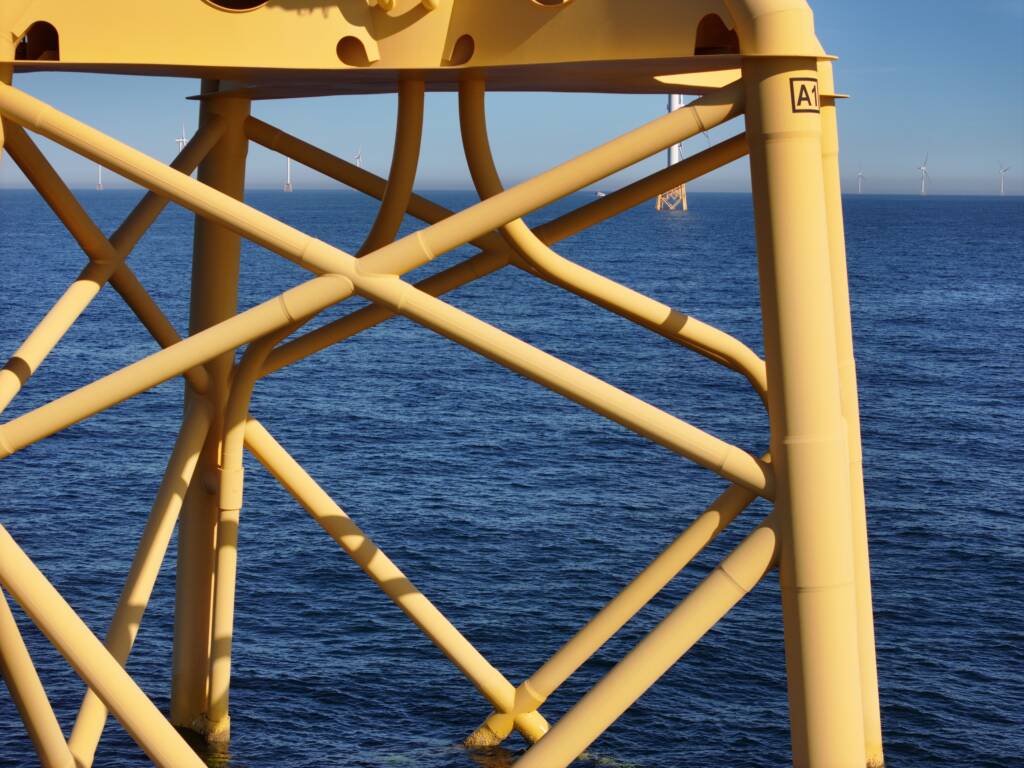

Offshore Wind Farm Inspections

Working offshore adds another layer of complexity — but drones make it much easier. With GWO-certified pilots and years of offshore experience, PB Aerial Imaging is fully equipped to conduct UAV inspections on offshore wind assets, reducing the number of personnel exposed to hazardous conditions.

Cost Savings and Operational Benefits

The financial case for drone inspections is strong:

- Lower labour costs – fewer technicians required on site.

- Minimal downtime – turbines inspected quickly and returned to operation.

- Better planning – high-quality data supports targeted, efficient repairs.

- Extended asset lifespan – regular inspections prevent small issues becoming expensive failures.

In short, drones save money while improving performance and safety.

Why Choose PB Aerial Imaging?

With over eight years of experience in offshore and onshore environments, full CAA approval, and GWO certification, PB Aerial Imaging delivers inspection services that are:

- Safe – prioritising people and the environment.

- Accurate – using advanced UAV technology and thermal imaging.

- Reliable – delivering clear, detailed reporting for your maintenance teams.

Take Your Wind Turbine Inspections to the Next Level

The renewables sector is moving fast — and inspection methods must keep up. Drone inspections are the smarter choice for operators who want to reduce risk, save money, and maximise efficiency.👉 Ready to upgrade your wind turbine inspections?

Contact us today for a free consultation and see how our UAV services can support your renewable energy projects.